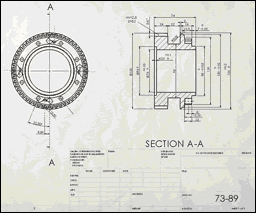

2D to 3D Conversion

Project Timeline : 90 days

Volume : 2000 drawings

Software : Solidworks / AutoCad

Requirement :

Our client had huge backlog of the old scanned drawings for which they wanted drawings to be drafted and 3D models so that they could focus on the new developments and products, at the same time wanted to optimally utilize their resources and manpower to add higher value.

Solution:

Sumpraxis highly dedicated and experienced engineers drafted drawings and converted 2D drawings to 3D models in a short span of time.

With efficient query handling and constant feedback from client’s end, our engineers delivered the desired output.

Our Client provided us with following :

The drawings received were in either .pdf, .jpg, .tiff formats along with the specifications.

Prototyping

Software : Solidworks / AutoCad

Requirement :

Our client constantly looks for innovation in their existing line of products or to introduce new products. This concept is highly innovative and required high value engineering assistance.

Solution:

There were no working samples provided by the client. All sketches provided were conceptual. Based on the information available as well as the objectives desired, an approach of study, analysis, design and prototype production is executed in a phased manner.

Our highly skilled engineering team provided following :

- 2 D Drawing and 3 D Model development on Solidworks.

- Identification of components to be developed

- Material Specs finalization

- Tool Design for prototyping

- Running a pilot batch of samples

- Fitment Test and modifications

- Pre production batch run

- Lifecycle testing Jig design / Execution of Lifecycle test.

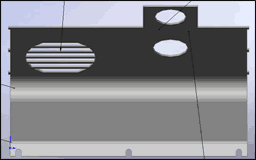

Reverse Engineering

Requirement :

Our client didn’t have the blue prints of the parts manufactured in order to remanufacture the old products or to innovate the new products using the old models.

Solution :

At Sumpraxis, our highly dedicated and experienced engineers did reverse engineering of their products using Solidworks.

The process involved following :

- Understanding the functioning of the sample

- Dissembling of the sample

- Creation of complete 3D/2D drawings (including parts, assemblies of the product).

- 2D Detailing.

- Material analysis/definition, checking robustness of the product, surface treatment analysis along with thickness of surface treatment.